A pre-assembled stainless steel manifold is up to 50% lighter than a brass manifold with the same size and features.

AISI 304L steel features a tensile strength of 520 N/mm2.

CW614N brass (used for manifolds) features a tensile strength of 430 N/mm.

Stainless steel has a mechanical strength 20,93% higher than brass.

Stainless steel manifolds, resisting to high and low temperatures, are perfect for installation in heating and cooling systems.

Stainless steel is aesthetically better than brass or polymer. It is also worlwide considered and recognized as “premium” material.

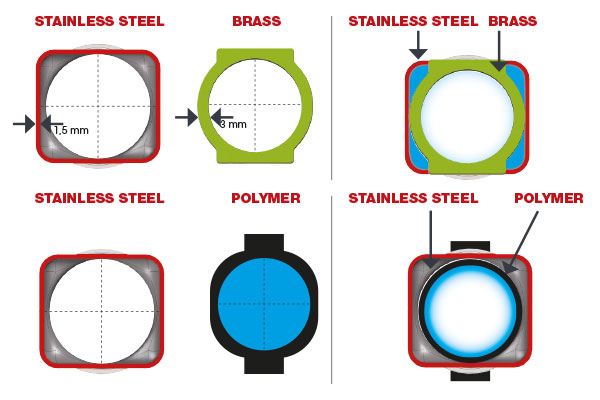

Thanks to an increased cross-section, stainless steel manifolds have a 20% higher flow rate than brass manifolds.

1” stainless steel manifolds flow rate is 5m3/h, 1” brass manifolds flow rate is 4,2m3/h.

No stress corrosion cracking and no electrolytic corrosion.

Plastic manifolds are sold in polymeric modular elements, usually reinforced with fiberglass; they must be jointed together by fixing elements ( i.e. blocks or fixing screws). Hydraulic seal is guaranteed by elastomers. This means that every joint is a possible leakage point. Stainless steel manifolds are produced in one single bar in every size from 2 through 13 outlets.

The stainless steel manifold with polyethylene shell is the best replacement of the polymer manifolds for cooling systems, with the advantage of having a significantly higher flow rate than the latter.

DOWNLOAD THE PDF VERSION: